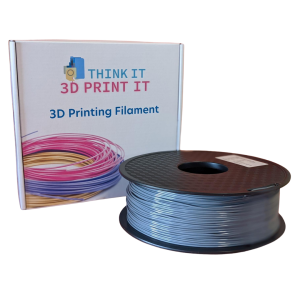

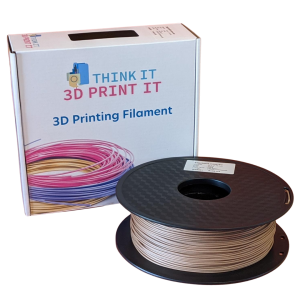

3D Print IT PLA+ Filament Wood 800g

$34.95

Free shipping on orders over $149!

- Satisfaction Guaranteed

- Local Stock!

- Secure Payment

- Australia Post Delivery

Description

3D Print It PLA+ Filament Wood 800g

PLA+ (Polylactic Acid) is one of the commonly used 3D printing filaments. It is the recommended material for many 3D printers because it is useful in a broad range of printing applications. It is odourless and low-warp. It does not require a heated bed. PLA filament is the most eco-friendly 3D printer material available. It is made from renewable resources E.g. corn-starch, sugar cane. 3D Print It PLA+ Filament Wood 800g for 3D Printing is available in a wide range of colours.

| Weight | 1 kg |

|---|---|

| Dimensions | 22 × 7 × 21 cm |

| Filament Colour | Wood |

Print Temperature:190 – 220°C

Hot Bed Temperature:0 – 50°C

Print Speed:50 – 110mm/s

What is 3D Print It PLA+ material?

PLA plastic or polylactic acid is a vegetable-based plastic material. It commonly uses cornstarch as a raw material. It is usually made from fermented plant starch. This material is a thermoplastic aliphatic polyester, and it is the primary natural raw material used in 3D printing. 3D Print It PLA is a fully biodegradable thermoplastic polymer consisting of renewable raw materials. Among all 3D printing materials, 3D Print It PLA is part of the most popular materials used for additive manufacturing for filament fabrication.

3D Print It PLA is a bioplastic, used in 3D printing using the FDM (Fused Deposition Modeling) technology, and along with ABS (Acrylonitrile Butadiene Styrene). This material is one of the standard materials used for 3D printing technology. We sometimes tend to compare these plastic materials, as they are the two most common alternatives available for consumer printers. 3D Print It PLA plastic material is easy-to-use and offers some intriguing mechanical properties.

Before you upload your file for printing, be sure to check the material design guidelines while creating your 3D file and before you send it for 3D printing.

What is PLA+ plastic used for?

PLA plastic material comes in the form of wire on a spool. This is fed into the extruder head, where the plastic is then heated until melted and deposited in a continuous extrusion onto the printing tray in layers. 3D Print It PLA has quickly become a popular material because it is more affordable to produce from renewable resources.

As it cools, PLA shrinks less than ABS. This gives it good geometric stability during the printing process. 3D Print It PLA can be beneficial for your product development, as it’s ideal for rapid prototyping. Large-scale 3D printing is the main advantage of the PLA, which can be a great benefit for a wide range of applications. The 3D Print It PLA printing filament is an affordable and versatile plastic. It can easily be used for prototypes, pattern making, tooling parts, or end-use parts.

Your quote is calculated on a series of factors, like the size, the volume, and the amount of 3D Print It PLA needed to manufacture your parts. Our team will always be honest and transparent regarding the price and the shipping time of your parts.

How does FDM 3D printing technology work?

During the 3D printing process, the filament is extruded through a nozzle which melts while being gradually deposited in layers on the build platform of the 3D printer until it is complete.

What colours are available for 3D Print It PLA+?

Your PLA parts can take on a variety of colours, with many colour options available according to your project specifications. Currently, we have black, white, grey, red, silver, blue, and wood 3D Print It PLA available. However please do not hesitate to get in touch if you require a different colour as occasionally we have other options available.

Reviews

There are no reviews yet.